2020年10月30日星期五

Log cabin woodshop

from FineWoodworking https://ift.tt/3ejsJf6

Fortnite Sign Via CNC

I wanted to make something special for my son Mateo’s 9th birthday. His favorite game is Fortnite so I thought it would be cool to pull in a graphic of his favorite skin (Agent Peely) and include his gamer tag in a carving. My new shop assistant Jon did all the heavy-lifting with the Powermatic CNC side of things and we tag-teamed the painting and finishing work. While this isn’t our usual kind of “project” I thought it would still be fun to show the process. And there’s nothing like making something in the shop that causes a kid’s face to light up!

The post Fortnite Sign Via CNC appeared first on The Wood Whisperer.

from The Wood Whisperer https://ift.tt/31SOnll

Missouri Bush Oil | Morning Show

Show notes coming soon.

The post Missouri Bush Oil | Morning Show appeared first on The Wood Whisperer.

from The Wood Whisperer https://ift.tt/2TBd8Or

Woodworker’s Journal – November/December 2020

The November/December 2020 issue of Woodworker’s Journal Magazine features a Cartographer’s table, Charging Table, Clocks and Holiday Gifts.

The post Woodworker’s Journal – November/December 2020 appeared first on Woodworking | Blog | Videos | Plans | How To.

from Woodworking | Blog | Videos | Plans | How To https://ift.tt/2HOZqFh

Video: How to Use a Spoon Mule for Greenwood Carving

from FineWoodworking https://ift.tt/3ecxyGX

2020年10月29日星期四

Face Frame Wall Kitchen Cabinet Template

One of the big reasons you'd want to build your own kitchen cabinets is to be able to customize the size. So I decided to create a template that is easy to adjust and customize on our sister site, Shelf Help, that has a free design configurator. Here' the links:

- Download free template for Frameless Wall Kitchen Cabinets

- Download free template for Frameless Base Kitchen Cabinets

from Recent Project Plans https://ift.tt/3jA1D4k

Face Frame Kitchen Base Cabinet Template

There are three big benefits to building your own kitchen cabinets: Customization and quality, and affordability.

When you build your own cabinets, you can choose better materials.

When you build your own cabinets, extras like crown moulding or open shelves or an odd size don't cost a fortune. It's actually quite reasonable!

But most important, when you build your own cabinets, you can customize.

No more filler strips. Place your appliances exactly where you want them. Go as tall as you want with wall cabinets.

To help you customize, I created a free design configurator that is super simple to use, and a template that guides you through constructing your own kitchen cabinets! Here's the links:

- Download free template for Frameless Wall Kitchen Cabinets

- Download free template for Frameless Base Kitchen Cabinets

Enjoy and please share if you build, we can't wait to see how your kitchens turn out!

Ana

from Recent Project Plans https://ift.tt/2HFQbay

Tools and Shops 2021 – Issue #286 is Available Now

from FineWoodworking https://ift.tt/3oElGCj

Online extras from FWW issue #286

from FineWoodworking https://ift.tt/31QVRVJ

Video: Tune your tenons with a rabbet plane

from FineWoodworking https://ift.tt/31QLqBx

From the editor: A shop to call home

from FineWoodworking https://ift.tt/2HK2aUo

2020年10月28日星期三

November/December 2020 Issue Preview

‘Tis the season to build gifts, and in this new issue you’ll have plenty of easy-to-build options! Good sense should dictate getting a head start on them as soon as possible, but we’ve got you covered — even if the holidays are already in full swing.

Cartographer’s Coffee Table: While this hasn’t been the best year to travel, we take the style of a vintage map-maker’s cabinet and give it fresh purpose with a thick top, stylish hardware and practical drawer storage. Call it our 2020 homage to wanderlust.

Cordless Charging Table: If you sometimes put off cell phone charging because of the hassle of plug-in cords, this veneered side table provides a hidden wireless solution that can top up your phone while you sleep.

Two Wall Clock Plans: Even in the digital age, analog wall clocks can still make practical and fun-to-make gifts. Here are two versions you can build with a CNC machine or a handheld router and Rockler’s number templates.

Four Simple Holiday Gifts: Gift-giving doesn’t have to be expensive if you’re a clever woodworker. These quick, easy projects can be made from scrap-bin cutoffs or careful culling from the firewood pile at next to no cost.

Woodturning: Wooden spatulas and spoons are ideal for today’s coated cast-iron cookware. Ernie Conover demonstrates the process of making both options.

Tool Tutorial: Sharpening tool edges doesn’t have to be tedious or time-consuming if you add some voltage to the process. Here’s a survey of several powered sharpening systems to consider.

Tool Preview: RIKON’s new VSR 70-3040 full-size lathe solves the problem of limited swing and spindle capacity with a stacked bed that grows at the twist of a knob.

Hardworking Woods: Red oak has been a mainstay in woodworking and cabinetry for a long time. Learn more about this practical and plentiful North American species.

Six Simple Finishes: Blotching can be a bugaboo when staining close-grained hardwoods like maple, birch or cherry. Here’s a simple finishing regimen to help avoid the problem.

What’s in Store: If Santa could use a few ideas for you under the tree, here’s a sampling of new products worthy of wrapping paper and a bow.

Get a One Year Subscription

The post November/December 2020 Issue Preview appeared first on Woodworking | Blog | Videos | Plans | How To.

from Woodworking | Blog | Videos | Plans | How To https://ift.tt/37QUIl0

November/December 2020 What’s in Store Roundup

Rockler Dust Right Edge-Routing Dust Port

The Art of Kumiko: Learn to Make Beautiful Panels by Hand by Matt Kenney

The post November/December 2020 What’s in Store Roundup appeared first on Woodworking | Blog | Videos | Plans | How To.

from Woodworking | Blog | Videos | Plans | How To https://ift.tt/3mJ1FJh

VIDEO: Rikon Lathe 70-3040 Overview

RIKON Power Tools has an industry-first solution for increasing capacity on its 70-3040 full-sized lathe. And it doesn’t involve change-overs or buying any extra accessories. You can increase both its swing over bed and distance between centers at the turn of a dial! This lathe’s solid-steel bed is double-stacked and interlocked on a rail system. Between the two beds, a separate 24-volt DC motor drives a continuous lead screw and actuator to slide the lathe’s top bed section open or closed. The mechanism is sealed inside a tubular casing with an IP54 rating, to protect it from dust and moisture. Powering it from fully closed to fully open takes about half a minute.

The post VIDEO: Rikon Lathe 70-3040 Overview appeared first on Woodworking | Blog | Videos | Plans | How To.

from Woodworking | Blog | Videos | Plans | How To https://ift.tt/37Ohfik

Turned Spatula and Spoon Pattern

These spindle-turned gifts are good exercises for practicing interrupted cuts.

The post Turned Spatula and Spoon Pattern appeared first on Woodworking | Blog | Videos | Plans | How To.

from Woodworking | Blog | Videos | Plans | How To https://ift.tt/3jFzMQ6

Coffee Scoop/Clip Template

Scoop your coffee with style and keep the coffee bag tightly sealed with these little wooden wonders. Download the template locating the scoop hole and clip slot for this project.

The post Coffee Scoop/Clip Template appeared first on Woodworking | Blog | Videos | Plans | How To.

from Woodworking | Blog | Videos | Plans | How To https://ift.tt/3kBPmOd

VIDEO: Making a Modern Clock Using CNC

Are you considering getting started in the world of CNC projects? In this demo, we’ll show you how the Shark SD100 CNC machine from Next Wave Automation works. And, we’ll make a nifty Mid Century Modern clock in the mix.

Download the CNC Files for This Project.

The post VIDEO: Making a Modern Clock Using CNC appeared first on Woodworking | Blog | Videos | Plans | How To.

from Woodworking | Blog | Videos | Plans | How To https://ift.tt/35CyfFC

VIDEO: Turning a Spoon and Spatula

Ernie Conover shows off his time-tested methods for making treenware, specifically a spoon and a spatula. You can find his patterns for cutting the general shapes at the band saw here. Then, he’ll take the blanks to the lathe to demonstrate the best methods for cutting the curved surfaces and handles.

The post VIDEO: Turning a Spoon and Spatula appeared first on Woodworking | Blog | Videos | Plans | How To.

from Woodworking | Blog | Videos | Plans | How To https://ift.tt/31Q89xD

Caleb Woodard’s career in carving

from FineWoodworking https://ift.tt/3jB08CZ

2020年10月27日星期二

2020 Guild Scholarship Recipients

This year our Guild scholarship distribution was handled a little differently. When Covid shut schools down in March we put out an open invitation to shop teachers in Middle & High School to reach out to us for help with their online learning plans. We had many requests and we were able to fulfill every single one because of the generous scholarship donations.

Even though this happened in March, we wanted to recognize the teachers teaching in such a challenging time and also thank the kind donations to help get all of these teachers set up in the Guild to share the videos with their students.

We will open our scholarship application again in May 2021. If you would like to donate toward the fund you can find more information here.

Guild Scholarship Recipients

Chris Davis

George Zubieta

Conrad Ackerman

Jonathan Au

Clint Behling

Brock Cameron

Giuseppe Tambasco

Rhona Kane

Thank you to the Scholarship donors!

Anonymous

Gerry Tolbert

Eric Lew

Peter Perrello

Frank Caserta

Amy Martin Pupo

David Nichols

Andrew Gibson-White

Raleigh Beringer

Andy Pridmore

Alan Lillich

Nathan Rewerts

Brian Walford

Brodie Brickey

Gordon White

Anonymous

Anonymous

Joe Romanowski

Anonymous

Anonymous

Anonymous

The post 2020 Guild Scholarship Recipients appeared first on The Wood Whisperer.

from The Wood Whisperer https://ift.tt/3e2eWct

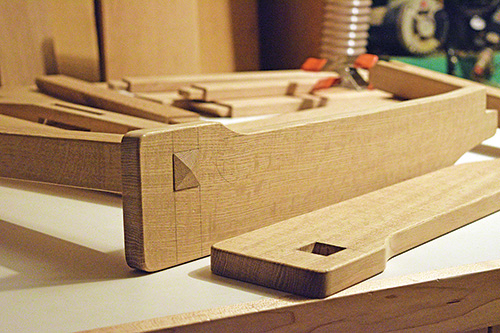

The Taper Maker

Over the years, I’ve made a lot of tapers. I usually cobble together a one-time use jig from scrap and throw it away when I’m done. And while there are a lot of tapering jig/sled designs out there I couldn’t find anything that inspired me enough to build or buy it. So I challenged my buddy Andy Klein with the task of coming up with a tapering sled that not only accommodates just about any taper I’d need to make, but also does it in a way that’s quick and easy to adjust. That’s what we’re introducing today: The Taper Maker

It features a single cam handle that adjust up and down as needed with three spring-loaded hold-downs. The sled can accommodate nearly 2.5″ of thickness on my saw and almost 36″ in length. It can be used for tapers as well as straight line rips for jointing operations.

We offer a hardware kit and plans if you’d like to make one for yourself. With most fancy tapering jigs on the market going for over $100, we think this is a great cost-effective solution.

By the way, if you want to see Andy using the jig for a cool project, check this out.

The post The Taper Maker appeared first on The Wood Whisperer.

from The Wood Whisperer https://ift.tt/3ow8qQf

Shiskabobbing My Uvula

00:00:34 – Good morning, it’s the Woodworking Morning Show

00:00:42 – Thanks to our Patreon subscribers and YouTube Members!

00:02:10 – Tee Shirt PreOrder ends Oct 31st and taper maker is for sale now!

00:07:05 – How often do you use the measuring tape on the miter station t-track?

00:08:30 – Happy Anniversary Spagnuolos!

00:11:43 – How much warping happens when lumber is air-dried vertically?

00:13:38 – How would you exhaust a room dedicated for spraying / finishing?

00:15:48 – What is the purpose of the inserts in a router table?

00:16:55 – How much of the bit needs to be in the collett?

00:18:05 – How can I learn more about the “why” in woodworking?

00:22:00 – Does Tasmanian blackwood compare to walnut?

00:22:45 – How do you make end grain look like it’s not laminated?

00:24:13 – When do you go with “quick and dirty” overdoing it “properly”?

00:26:40 – Do every inch of projects need to be finished or do you leave interiors and corners?

00:28:15 – Is walnut safe for furniture for pets?

00:30:40 – What’s the best way to store plans where they’re not going to rust?

00:32:10 – Woodworker’s Fighting Cancer update. We reached our goal!

00:33:23 – How does the guild discount work for the Roubo build?

00:33:50 – Is Bell Forrest doing a black Friday sale against this year?

00:35:20 – How deep should a dowel joint go?

00:37:30 – Do you have a video of applying Rubio to furniture?

00:40:30 – Do you have a detail on the different spokeshaves on the wall?

00:42:37 – How do you protect your phone/camera/electronics in the shop?

00:43:47 – How can you stop the floor moving in your shop?

The post Shiskabobbing My Uvula appeared first on The Wood Whisperer.

from The Wood Whisperer https://ift.tt/31O4mRu

No Tricks Here

One of my favorite holidays is soon to be here. I really like Halloween, because on a normal year, I get to see the costumed kids walking the neighborhood. That’s big fun, and I always buy more candy than we could possibly hand out. The extra somehow finds its way to my shop, so there’s no bigger win/win in my book. But this is not a regular year…I don’t know about you, but my candy consumption has been at a high level for the last eight months.

One of my favorite holidays is soon to be here. I really like Halloween, because on a normal year, I get to see the costumed kids walking the neighborhood. That’s big fun, and I always buy more candy than we could possibly hand out. The extra somehow finds its way to my shop, so there’s no bigger win/win in my book. But this is not a regular year…I don’t know about you, but my candy consumption has been at a high level for the last eight months.

The kids around here have been wearing masks and hanging out in the neighborhood all summer (same as me). Even so, my grandchildren are laser focused on the holiday —as the blaster project mentioned last week demonstrated.

So have some fun with the scary holiday, however you can make it work. And then, onto holiday gifts (unless you have completed them already…yeah, right).

Rob Johnstone, Woodworker’s Journal

![]()

Willie Sandry: An “All In” Woodworker

From drying his own lumber to stitching leather cushions, Willie Sandry is a soup to nuts maker..

![]()

How to Apply Milk Paint

From Our Sponsor

|

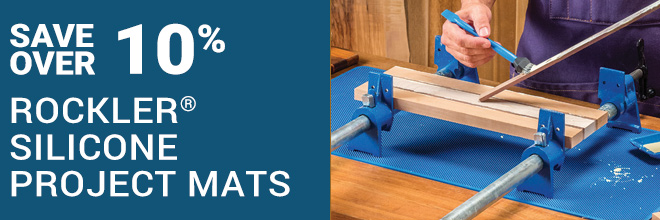

Protecting your workpieces – and your work surfaces – is as simple as a single word: silicone! Rockler Silicone Project Mats are the perfect solution to avoid marring or scratching when working with fragile or previously finished materials, and to contain messes from glue-ups, finishing, and other projects that might otherwise damage your bench top or work table. |

FREE SHIPPING: $39+ Orders. Additional shipping charges will apply for select oversized items, express orders, international orders, and orders to Alaska, Hawaii, Guam, Puerto Rico, and the Virgin Islands. Rockler reserves the right to limit quantities, correct errors or omissions and modify or end this promotion at any time. Neither 15% off nor FREE SHIPPING can be combined with any other offer or applied to previous orders. Not valid with Rockler’s Professional Catalog and independent resellers. Offer ends 11/25/20.

The post No Tricks Here appeared first on Woodworking | Blog | Videos | Plans | How To.

from Woodworking | Blog | Videos | Plans | How To https://ift.tt/35GXSF5

Video: Testing the wall-mounted dust collectors

from FineWoodworking https://ift.tt/2Twc12h

Halloween Shop Projects

Last week, Rob shared that he’s spending some shop time with his granddaughter these days and wondered what Halloween projects you might be churning out. Several of you have shared. – Editor

“I knew the day would come when the grandkids would not find us magical anymore. Grace will be 18 next month. Noah was 15 in August. They have their own schedules. Grace drives. Noah plays computer games with his friends. Nowadays, we are just old people. But a while back all of us had fun with projects. The treehouse was their favorite. One side was a castle with princess Grace. The other side was the Black Pearl with captain Noah. There were shop-made swords that knighted grandpa and Noah on a regular basis. The Black Pearl, when I donated it to the young kids two blocks away, had over 100,000 miles in her log. We visited all seven continents and fended off hundreds of pirates with a shop-made canon that fired ping pong cannon balls into the neighbor’s swimming pool. The catapult was not my idea … Noah made me build it. The small bags of mulch that landed on the neighbor’s car did no real damage. A dry towel and a leaf blower and no one ever knew. If you have a woodworking shop and kids or grandkids, take the time to make some magic and enjoy the time together.” – Bruce Adams

“Over the last few weekends, my daughter and I have been going through our scrap-wood pile and making holiday decorations for our yard and for a friend of ours who recently moved to the area. We still have to make a ghost or two and a witch to round out the collection. My daughter is still a little too young for the power tools, but she was very excited to help ‘direct’ the project and apply paint. It has been fun to have her out in the shop with me working on something that she will see for years to come.” – Tom Hanley

“I have made some of these ‘Pumpkin Folks’ ornaments.” – Ron Chamberlin

The post Halloween Shop Projects appeared first on Woodworking | Blog | Videos | Plans | How To.

from Woodworking | Blog | Videos | Plans | How To https://ift.tt/2Tvcthq

Walking around the new property (and why I'm not turning the barn into a shop)

from Matthew Cremona https://www.youtube.com/watch?v=gFB8xnADK9M

Pine(ing) for Perfection

from FineWoodworking https://ift.tt/3dZHfIy

2020年10月26日星期一

How to chainsaw a bowl blank from a tree

from FineWoodworking https://ift.tt/3mn2UNV

2020年10月25日星期日

Face Frame Kitchen Cabinet Template

There are three big benefits to building your own kitchen cabinets: Customization and quality, and affordability.

To help with customization, we created this tutorial as a template on Shelf Help, where you can use the design configurator for free to figure all the cuts needed to build. Click here for the free template for face frame kitchen cabinets.

from Recent Project Plans https://ift.tt/34sRMJ9

2020年10月24日星期六

6 Guru-Level Tips for Setting Up A Small Shop

from John Heisz - I Build It https://www.youtube.com/watch?v=I4nWTeIzR94

Octoprint for the 3D printer and big project announcement (Random Shop Stuff 25)

from Marius Hornberger https://www.youtube.com/watch?v=iFhVSmMzOLg

2020年10月23日星期五

VIDEO: How to Apply Milk Paint

Traditional milk paint comes as a bag of powder, and it’s been gaining a lot of traction in woodworking circles in recent years. It’s one of the oldest forms of paint, and I think there’s an authentic nostalgia to using it. It contains limestone, casein protein — which is where the milk comes in — and natural earth pigments that provide the color. The powdered paint must be mixed into solution with water before use.

General Finishes has taken a different approach to their milk paints. It still has a limestone base, like traditional milk paint, which gives it that flat sheen and great durability. But it’s formulated to be more user-friendly and economical.

The paint comes premixed in a can to the correct ratio, so with a little stirring it’s ready for use. It has a much thicker consistency than typical home center paint, yet it can be brushed, rolled or sprayed. And, it has very little odor when wet. When you’re finished, GF Milk Paint cleans up with soap and water.

The post VIDEO: How to Apply Milk Paint appeared first on Woodworking | Blog | Videos | Plans | How To.

from Woodworking | Blog | Videos | Plans | How To https://ift.tt/2TkoAOf

DiResta 90: Chevys, Go-Karts & Guitars

from jimmydiresta https://www.youtube.com/watch?v=S691uodkWdg

Dowel Key Miter Joints

STL227: Tom McLaughlin is serious about square

from FineWoodworking https://ift.tt/3jmvNYD

Add color and texture to a turned bowl

from FineWoodworking https://ift.tt/2Tm34bL

Woodturning - Goblet from a Piece of Plum and Epoxy Resin

from UWOODWORKER https://www.youtube.com/watch?v=f7H4NiWFOjU

2020年10月22日星期四

Ten EXPENSIVE woodworking tools you have to see!

from Stumpy Nubs https://www.youtube.com/watch?v=BtpkbYCnwpI

Testing Bimetal Bandsaw Blades Against Embedded Metal

from Matthew Cremona https://www.youtube.com/watch?v=euVanVFtsww

Two Story 18" or American Girl Dollhouse

The free plans for this dollhouse are designed by me and available for free on our sister site, Shelf Help. You can cut the plywood yourself or have us do it for you through the Shelf Help link. If you do choose to cut your own plywood, also add edge banding to the front edges of the plywood to finish them out.

from Recent Project Plans https://ift.tt/3dM94nK

Why not just use a shopvac for my router table? (vs. custom blower)

from Matthias random stuff https://www.youtube.com/watch?v=vc5Dr_Sb25E

Kumiko: An Exercise with Components in SketchUp

from FineWoodworking https://ift.tt/35oE1uj

Vlog 160: She Stole The Show

Webinar: No-Stress Hinge and Lockset installation

from FineWoodworking https://ift.tt/37tfCqc

2020年10月21日星期三

Willie Sandry: An “All In” Woodworker

When Washington-based woodworker Willie Sandry gets excited about a project, he jumps in with both feet. And considering he’s a physical therapist, he can take these leaps forward without hurting his back.

“My biggest reward of PT is inspiring someone to turn a sedentary life into one filled with fun, useful activities.”

As a young man, Sandry would help his father, a contractor, build decks and refinish floors during summer breaks from school. Two uncles — one a boat builder and the other a woodcarve — also were early woodworking influences.

Sandry’s mother, a writer, helped shape his publishing pursuits, too. “In the most basic sense, I build things and write about them,” Sandry says. “Talk about the acorn not falling far from the tree!”

Over the years, Sandry has gravitated toward Arts & Crafts style furniture, and we’ve published several of his projects embracing this aesthetic. He’s developed a particular fondness for Charles Limbert.

“Sometimes I’ll do Limbert reproductions, trying to match every angle and dimension. Other times I’ll let functionality guide the design and add in cutouts and inlays reminiscent of a Limbert piece,” Sandry says. “Limbert used angles, curves and cutouts in a recipe that almost always produced a beautiful piece.”

Among his résumé of projects, Sandry says the one he’s just completed is often his favorite. But a special example that stands out is a master bedroom suite that includes a bed frame, dressers and nightstands. He’s also pleased with his Limbert Hutch.

Sandry’s work demonstrates a high degree of skill. But of course, no one becomes a talented woodworker overnight. Sandry admits that it’s taken many years to gain proficiency with the craft. He feels the evolution of his skills started with the ability to make joints fit together well. Then, he focused on his project design skills, and last came the ability to apply a sprayed finish well.

Adding More Skills

A number of years ago, the high cost of buying kiln-dried, quartersawn white oak lumber prompted Sandry to build a lumber drying kiln. Aside from cost savings, the kiln also helps him better control his lumber’s quality.

“It changes the whole way I look at my lumber supply,” Sandry says. “I don’t calculate down to the board foot anymore. I buy by the stack and not by the board.”

Arts & Crafts has even inspired Sandry to try his hand at leatherwork. When he wanted to sew leather cushions for a Morris chair and ottoman years ago, he took a class to learn how.

One aspect of the woodworking process Sandry has decided against is sawing boards directly from the log.

“I debated about buying a band saw mill one year, but that same year a log rolled onto a sawyer friend of mine. He broke his pelvis, and it forced him to retire early,” Sandry recalls. “Right then and there my wife made me promise I wouldn’t get a lumber mill.”

But provided he stays away from bucking logs, Sandry says his wife “heartily” embraces and encourages his woodworking. It’s also sparked interest from his twin teenage sons who occasionally build with him.

Sandry’s woodworking is an avocation that continues to offer new opportunities for both learning and enjoyment. “If a chair needs a leather cushion, let’s sew one. If a cabinet needs a leaded glass panel, get out the soldering iron and let’s do this thing. And if someone reads about my work and is inspired to make something like it, well that’s just the cherry on top of it all, my friend.”

The post Willie Sandry: An “All In” Woodworker appeared first on Woodworking | Blog | Videos | Plans | How To.

from Woodworking | Blog | Videos | Plans | How To https://ift.tt/34ikf4t

Making Dexter's Blood Slide Box For Bluray Disks - Woodworking

from John Heisz - I Build It https://www.youtube.com/watch?v=GC9b_BwLo3w

2020年10月20日星期二

Halloween Construction

Later this week, my eldest grandchild, Maggie (8 going on 9), and I will be making her a set of “blasters” to complete her Halloween costume. The blasters (non-working models) will be made of wood, but painted in such a way that all the other kids will likely think she got them from Blasters R Us. We will see, since Maggie is in charge of the painting.

Later this week, my eldest grandchild, Maggie (8 going on 9), and I will be making her a set of “blasters” to complete her Halloween costume. The blasters (non-working models) will be made of wood, but painted in such a way that all the other kids will likely think she got them from Blasters R Us. We will see, since Maggie is in charge of the painting.

All this has me wondering what sort of Halloween contributions will be coming from your shop. There are many ideas that come to my mind … gravestones, zombie parts, maybe a working model of a guillotine.

But as fertile as my imagination is, I am certain that my fellow woodworkers are much more creative and productive. Hence, I will wait to hear from you on the matter.

Rob Johnstone, Woodworker’s Journal

![]()

Tool Chest Project

Help keep your hand tools and other small supplies organized and at the ready with this easy-to-build, two-drawer tool chest.

![]()

Power Carving Wood Art

From Our Sponsor

|

When you need to cut multiple cross lap joints with uniform spacing, reach for the Rockler Cross Lap Jig. Screw it to your miter gauge and use it with your table saw and a dado stack to cut the half-lap joints for anything with a wooden grid: lattice, wine racks, grilles/mullions for glass doors, and torsion boxes for your workbenches and table tops. |

FREE SHIPPING: $39+ Orders. Additional shipping charges will apply for select oversized items, express orders, international orders, and orders to Alaska, Hawaii, Guam, Puerto Rico, and the Virgin Islands. Rockler reserves the right to limit quantities, correct errors or omissions and modify or end this promotion at any time. Neither 15% off nor FREE SHIPPING can be combined with any other offer or applied to previous orders. Not valid with Rockler’s Professional Catalog and independent resellers. Offer ends 11/25/20.

The post Halloween Construction appeared first on Woodworking | Blog | Videos | Plans | How To.

from Woodworking | Blog | Videos | Plans | How To https://ift.tt/35ftvWh

Vision, Design, Build

(By Helen)

Ending up with a nice piece of furniture that you’ve made yourself is pretty satisfactory.

But there’s more to worry about than just cutting the joints or polishing up the finish.

Sometimes the hardest part is choosing what to build. And often it’s easier to come up with something from scratch than trawl through plans that are available, hoping to find something that perfectly meets your needs.

Continue reading at The English Woodworker.

Haven Technologies Introduces ISOtunes LINK Bluetooth Earmuff Hearing Protection

from FineWoodworking https://ift.tt/37qFrHd

285-Tool Review: Woodpeckers DelVe square

from FineWoodworking https://ift.tt/3kes5S4

Distractions Discussed

Last week Rob wondered what sorts of issues, besides heating and cooling, prevent you from spending more time in your shops. Several readers share their thoughts. – Editor

“COVID 19 has really been distracting me! I live in a condominium complex for people 55 years and over. For the last four years, we have had a beautiful fully functioning wood shop: 22′-6″ wide x 50′-0″ long with air conditioning, heating, high ceilings, big windows and a very good lighting system. Three years ago, the shop was in pretty bad shape. I drew up plans for a remodel and presented them to the board of directors with a budget of $2,200 that they approved. The board also approved a separate request for a new $3,500 SawStop table saw. We have a long list of high-quality tools and accessories in our shop. Unfortunately, our whole complex, and all amenities, was shut down on March 13. So, seven months with no woodworking! I have big withdrawal pains, because I’m 75 and have been involved with wood since I was 15. Unfortunately we will not be able to open until sometime next year. I miss the wood shop! Take pity on me!” – Bob Wollweber

“The following is a list of things that distract me, in no particular order:

- Taking care of the house, because the house never learned to take care of itself.

- Other hobbies, as you need another hobby to distract you to keep you interested in the first hobby.

- Gravity Cat. That’s the invisible cat that always knocks things off the workbench at exactly the wrong time.

- The real cats. They are the ones laughing at you because of Gravity Cat.

- Lousy sight. Especially when one brushes the blade of the handsaw over several fingers.

- The Internet, because I am always looking for that next best project for the next lifetime, when there is time to do it.

- The magazines. Looking forward to the next Woodworkers Journal, to skim through and know that I will get back to it, along with the other five year’s worth of periodicals.

- My sense of humor, because I will search my brain for the next gut-buster to tell my wife and see her laugh.

- Videos. Videos of woodworking, videos of cats, real and not real, videos of my other hobbies, even magazine videos, and videos to make one laugh.

- This is a short list, but so is a small boat that ran aground.” – Carl Timko

“In April of this year we moved about 160 miles, and my shop space went from a total about the size of a two-car garage, down to a one-car space. We have a three-car garage, but I only get one space for the workshop. All my tools are still surrounded by “stuff”, some of which will eventually be unpacked and moved into the house, and some will remain stored in large cabinets that, surprisingly, were already installed (a bonus, you could say). We will build a solid wall with a door to separate the shop, and its attendant sawdust, from the automobiles that will both now reside under cover — another improvement from our previous residence. I am now starting the process of building that wall; not a small task at age 81, but I do have some help. I hope to get the wall done in the next two weeks, but I still will not have easy access to power … extension cords will have to fill the bill for a little while longer until I can afford the cost of new wiring. While I have only two or three 110-volt outlets, I am able to do some very small projects/repairs without too much grief about the sawdust. The entire garage is well-insulated, so heating and cooling are not likely to be a big issue throughout the year. I’m hoping that I will be able to complete my Christmas gift projects before the holidays are upon us. It will most likely mean some late evenings as the calendar is relentless and unforgiving.” – Gordon Patnude

“I have been watching the terrible fires out West and the devastation they have caused along with the storm damage from hurricanes along the Gulf Coast. I believe there are many woodworkers who were wiped out. Trying to deal with insurance adjusters on replacing the tools is a daunting task. As a 74-year-old, I have been stocking my shop for over 50 years with new, used and inherited tools. Last year I started an inventory using Google Spreadsheets as they are free and stored on the Cloud, so I can access them with any computer anywhere. I don’t have to have my original computer or a thumb drive that might get destroyed. I believe it would be a great service to your readers to run a series of articles on setting up a shop inventory on their personal computer using Google Apps.” – Michael McDonald

The post Distractions Discussed appeared first on Woodworking | Blog | Videos | Plans | How To.

from Woodworking | Blog | Videos | Plans | How To https://ift.tt/2HjOdML

2020年10月19日星期一

Simplified 8' Barn Door Console Plans

Want to make your living room instantly gorgeous (and tidier)?

A barn door door console can change everything!

Instead of paying over $1000, have you thought about building it yourself?

- No particle board

- You choose the finish

- Rustic look from using solid wood

- Save hundreds of dollars - we estimate building it yourself will cost about $350

Let Me Do The Hard Part

Don't have a truck or a table saw to cut the plywood?

I can help!

Let me ship the plywood pieces to your front door, precisely cut on a factory panel saw, with the front edges finished. Since you only pay for exactly what you need (no scraps) and you don't have to buy edge banding, the price is only a little more for all this convenience and accuracy. And you don't have to go out and buy and store a big, expensive, dangerous table saw.

Click here to purchased the customized kit for this Barn Door Console Plan.

Want to do everything yourself? No problem - we have the plywood cuts listed in the cut list too.

from Recent Project Plans https://ift.tt/3kfVTO7

2020年10月18日星期日

2020年10月17日星期六

The Best Trim Router I’ve Used: Milwaukee M18 FUEL 2723-20 Compact Router

Wood Pumpkin Treat Holder

We love these fun, festive pumpkins at the front door! They make festive planters or treat holders for trick or treaters.

This is a very easy DIY project, perfect for a beginner. These pumpkins are fun to customize, and they are almost impossible to mess up!

You can use pallet wood or fence pickets. With fence pickets, my project cost $8!

I went with a Farmhouse theme, because I'd like to use this wood pumpkin as decor through Thanksgiving.

We are so excited to present trick-or-treaters with this beautiful help yourself display.

It's so easy to make. I made mine with a jigsaw and a hot glue gun (NO Drill or screws or nailer required).

See free plans below:

from Recent Project Plans https://ift.tt/3nYffJX

2020年10月16日星期五

How to acheive perfect alignment and repeatability at the CNC router (with bench dogs)

from Marius Hornberger https://www.youtube.com/watch?v=Unq36TDp5BQ

Pumpkin Treat Holder

We love these fun, festive pumpkins at the front door! They make festive planters or treat holders for trick or treaters.

This is a very easy DIY project that you can make using just a few tools.

Here's the steps:

from Recent Project Plans https://ift.tt/3lUOy76

Damascus Of Broken Bandsaw Blades

from Black Beard Projects https://www.youtube.com/watch?v=tNFNkfDwBco

2020年10月15日星期四

Workshop Tip: Shopmade clamp squares up any carcase

from FineWoodworking https://ift.tt/3lQAwUe

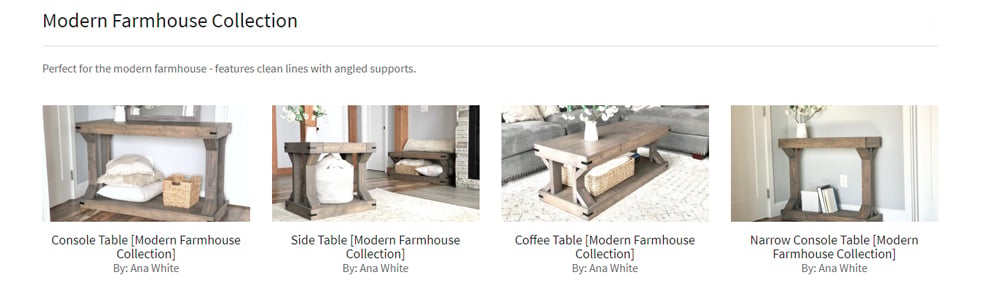

Writing Desk [Modern Farmhouse Collection]

Our Modern Farmhouse Collection of plans has been quite popular, making living spaces more functional and beautiful everywhere, all with just a few tools.

All the rustic charm, but in a fresh, new form. We love it!

We love it so much, we are adding a NEW plan to this collection. The Modern Farmhouse Desk.

I partnered up with Ryobi to get you this brand new plan!

Click HERE to download the free plans from Ryobi Nation now.

from Recent Project Plans https://ift.tt/3k38Meu

Milwaukee M18 FUEL 2840-20 Electric Compact Quiet Compressor

2020年10月13日星期二

Fix a paint brush with varnish dried in it

from Matthias random stuff https://www.youtube.com/watch?v=jCKxsii02SQ

2020年10月12日星期一

How to cut a straight line with a router bit

from Stumpy Nubs https://www.youtube.com/watch?v=vByk6usBU_8

Hot Topic

Last week I mentioned that I was adding heating to my shop. Then I asked how you all had attacked the heating challenge (as well as cooling). Boy howdy, you had a lot to say on that topic, and you can see those comments in the Feedback section. Thank you for the input! It appears that our surveying was accurate about heating and cooling as a significant challenge to spending more time in your shop.

Last week I mentioned that I was adding heating to my shop. Then I asked how you all had attacked the heating challenge (as well as cooling). Boy howdy, you had a lot to say on that topic, and you can see those comments in the Feedback section. Thank you for the input! It appears that our surveying was accurate about heating and cooling as a significant challenge to spending more time in your shop.

So now I want to know what other things keep you from your sawdust-making rounds. Do soap operas take up your time? Are there social media feuds to fend off? Perhaps your honey-do projects outside the shop are expanding by the hour? Whatever the case, this inquiring mind wants to know.

Rob Johnstone, Woodworker’s Journal

![]()

Mobile Lathe Stand

Put your mini lathe on the pedestal it deserves. While our art director’s design isn’t fancy, it’s solid, economical and easy to build. Dress it up with accessories as you like.

![]()

Advice for Moving a Full-Sized Lathe

From Our Sponsor

|

The innovative Dust Right Lathe Dust Collection System is designed specifically to cradle your workpiece when it is chucked in the lathe and catch most of the dust and debris as you complete your turning. So crank up that lathe – we’ll help take care of the mess! |

FREE SHIPPING: $39+ Orders. Additional shipping charges will apply for select oversized items, express orders, international orders, and orders to Alaska, Hawaii, Guam, Puerto Rico, and the Virgin Islands. Rockler reserves the right to limit quantities, correct errors or omissions and modify or end this promotion at any time. Neither 15% off nor FREE SHIPPING can be combined with any other offer or applied to previous orders. Not valid with Rockler’s Professional Catalog and independent resellers. Offer ends 11/25/20.

The post Hot Topic appeared first on Woodworking | Blog | Videos | Plans | How To.

from Woodworking | Blog | Videos | Plans | How To https://ift.tt/311JV3b

Climate Conversations

When Rob mentioned last week that woodworkers are often challenged by heating and cooling issues in their shops, he wasn’t kidding! Many of you have written in to share your solutions for creating a more comfortable workspace, in spite of Mother Nature. – Editor

“I have a wood/coal burning stove made with a kit and a 55-gallon barrel. It has an electric heat capture ‘radiator’ mounted in the vent too, that heats. A fan blows through it, adding a lot to its efficiency. If I’m just out doing something quick and in one spot, I use an electric heater. I also have a radiant catalytic heater head (Big Buddy) that mounts on top of a 5-gallon propane tank that works very well if I’m not doing anything easily flammable. Luckily, I live at elevation in Colorado, so a box fan in the summer is normally all I need.” – Rick Corbitt

“I took a gamble and bought a one-ton (12,00 BTU) mini-split system made by a company called Aux who seems to sell a load of systems in Mexico. I installed it myself, which was easy, and a friend who had a vacuum pump and set of gauges finished the install and got it running. The unit cost $500, including the shipping. The experiment worked out well. Last winter it was on all the time, set at 60 degrees, which made the shop (separate building) completely livable. This summer it was on A/C all the time at 80 degrees, which was wonderful. For the minimal cost, it’s the best thing I’ve ever done for myself, and the efficiency is surprising. I have hardly noticed it on the electric bill, and it makes my puttering around the shop more comfortable.” – Paul Clipper

“My suggestion: I burn the wood from my previous ‘loser’ projects. Actually, I bought a radiant heater from Costco that they usually sell this time of year. That way I don’t have to heat the entire garage or outside. It focuses the heat where I need it.” – Bill Cecil

“My shop in located in north Georgia, but it still gets cold. I heat my shop with a woodstove. I can eliminate scraps easily in the winter, turning money spent on the wood into heat rather than just thrown out. Summertime cooling is done by opening the doors, fans and dressing light, because it does get hot.” – Tom Snyder

“I am a part-time hobby woodworker and live up in Maine. We have cold and severe cold to overcome. I have two small woodshops, one 10′ x 16′ I have had for some time and am finishing up a 12′ x 14′ that I will be putting a CNC router in. Both of them are run on generator power for all the tools, and I am heating both with small furnaces I got out of old pop-up campers and run off a large grill LP tank and a 12-volt battery with a trickle charger. If I know what I am working on, I will go out in the morning and start the furnace. Then, after breakfast, it’s all ready to go. I also have one that I made portable in a wood box and can set it up as additional heat. I have a small exhaust pipe port so I can set it inside and exhaust the fumes. I pay for a battery trickle tender and a few tanks of propane a year. Not too bad for what I need. When I fully retire, I may look into something more permanent. For now it works great.” – Jared Young

“I’m 20 miles north of Grand Rapids, Michigan, on the east side of a lake. Yup, cold winter winds pouring out of the west, across a frozen lake, chilling my work space. For years, my 24′ x 30′ garage with a large attic was not heated because it wasn’t insulated. But a year ago, we installed wrap-on and vinyl siding. We wired it up for better lighting and plug-ins, then insulated the ceiling and walls and put up drywall. All the work was done by my son and me. We have natural gas at the house, but it’s 100 ft. away down a hill, and between it and the garage is a septic and drain field. To tap into the main line running from the road would have required putting a separate meter on the garage, and I wasn’t quite ready for that. I had a used propane downflow forced-air wall heater with two 20 lb. and two 30 lb. tanks with an auto switching valve, so I installed it, built a sealed box in the corner of the garage and vented it to the outside for the tanks to fit in. I only keep the garage at about 50 to 55 degrees to keep the chill off when it starts to get cold, and that costs about $100 per month. I find that I work well in that temp, and keeping the concrete floor warm helps a lot. I have thought of going to a more efficient furnace, but where do you stop? Not sure what it would cost to have the local utility company trench in a new line and install a meter for me, and I have not priced a new updated furnace. I know it would reduce my monthly cost, probably even give me an additional 10 degrees for free, as well as pay for itself. But at 72, I just don’t know. I’m not yet a major woodworker, but I did buy a lot of woodworking toys before retiring after 40 years in tool and die. Since updating the garage, I started building sound-proof drum rooms for churches so they can control the loudness of the drums through a sound board to match the other musicians. That way, grandma in the front row isn’t having her ears blown out, should the drummer get excited. I’ve built three so far and I find it challenge and rewarding.” – Mike Dennis

“I used to use a downdraft oil furnace (from a mobile home). It heated very quickly, but getting the oil became a problem. I switched to an overhead electric heater. Takes longer but is a lot easier, especially for a senior.” – Ians

“We live in northwest Wisconsin, and I just built my new shop last year. It is a 9′ x 30′ x40′ room inside a larger pole barn. We had radiant floor heat added in the shop during the concrete pour, which I keep set around 55° to keep the chill off. Because radiant floor heat can take hours to alter the temperature, and that I don’t want to pay for comfortable heat 24/7, I added a mini-split. On cold days when I do want to work in the shop, I just trip the mini-split, and it’s shirtsleeve temps in just a few minutes. On the flip side, the mini-split also provides my summer cooling as well.” – Kim Randall

“I am in southwest Ohio. My shop is 14′ x 28′. When I built it, I insulated the ceiling, walls and floor well. I use one of those heat/AC combo devices that is very similar to those you often find in hotel rooms. If I remember correctly, it is called a C-PAT or C-PAC. I never have to run it on high, and it does a great job of keeping me quite comfortable. I also have a roof exhaust fan to remove the heat from the attic.” – Carl Brown

“I live in Upstate New York where the temps sometimes fall below what is comfortable in the shop. When I used the furnace for heating, the shop stayed warm enough for me to work down there in the wintertime. However, I have been heating the upstairs with a coal stove for the past 12 to 15 years, so I needed to come up with a way to heat the shop. My shop is roughly 26′ x 50′. I thought that installing an electric heater would be the perfect answer. I bought the heater and installed it myself, since home wiring is pretty basic. But I’ve found I cannot afford to run the heater. It does a fine job if I had a small fortune to spend for my shop to be cozy warm. A coal or wood stove would be ideal in the basement, but then again, the cost for pipe and stove, even if I installed it myself, is more than I can afford since I am retired. I bought a small propane space heater that runs tanks you might find on a gas grill. It does a fine job, but the wife complains about the fumes it gives off. If I had gas in the wall, a no-vent gas heater would be ideal, but I do not. The space heater works well for as long as it is running, but then the shop cools down again. I can’t afford to run the monster electric heater that I installed, and you need to run it all the time if you want to work in the shop or do any finishing or gluing. The only way I’m going to have a warm-enough shop to work in is if you start a ‘Go Fund Me’ page to pay for heating my shop. A wood stove is my best hope, but I use a lot of the scraps that would feed the thing. You probably should start that Go Fund Me page right now, because the Farmer’s Almanac is forecasting a severe winter.” – jrouleau

“We live in central Texas, so we have extreme summer heat. Shop cooling was a big problem. Several years ago, we added on a single-bay garage and an attached single-bay carport. You can guess who has the privilege of parking in the garage. This arrangement allowed the original two-bay garage to be fully converted to my shop. The shop is fully insulated and attached to the house. After trying the floor-standing portable air conditioner approach, I decided to go another direction. The downstairs air handler for the heat pump is located in the attic of the shop. After much consideration, I decided to try connecting to the downstairs air handler. Since I did not mind a wider temperature range in the shop than is acceptable in the house, I installed a thermostat in the shop to control only the electric dampers I placed in the supply and return ducts I ran to the shop. So if the downstairs unit is running and the temperature in the shop exceeds the set point, then cool or warm air is supplied to the shop. The system has worked quite well. The steel tools no longer require protection from rust, and I don’t become dehydrated or frost bit. The obvious question is: what about fumes and dust recirculating into the house? To assist in minimizing that problem, I placed a filter on the shop return duct. Some fumes from finishes do enter the house, but that has been acceptable. The cost of the equipment was minimal, especially when compared to the cost of a separate heat pump, and I have a wonderful shop to use to construct all manner of wooden objects.” – Don Francis

“Since I have only a smallish two-car garage shop, I struggle with heat and cold. I have offset the heat problem somewhat by installing a 52″ ceiling fan over my workbench (I know, I know, the dust problem). But I also have a three-speed JET dust filter installed as well as two 20″ box fans that I plan to mount in a rolling tower that I can move to where I’m working. Heat is another problem. I live in a 55+ community with a dastardly HOA, so altering the space is out of the question. If I could, I would install one of those combo heat/air units like those found in many motel rooms. But alas, I cannot. So for now, I will have to deal with the cold as best I can. Fortunately, I live in Tennessee, so it is often a little less unbearable.” -Jerry Price

“Fortunately, my shop here in Upstate New York is in my basement. So is my home furnace, right at the edge of my shop space (which I wish it wasn’t; then I could easily have more shop space). So in the winter I get enough residual heat from the furnace and hot air ductwork to keep the entire basement at 60+ degrees. And in the summer, all the poured concrete walls and floor keep the temperature down in the 60s as well.” – Rick Bird

“For me here in Texas, it’s a compromise between needs and wants. I have a small work area, so there’s less to heat and insulate. I use a small oil space heater near my task center, which gets me by. For large projects I open the door during the warmest part of the day. I use fans in summer, but some days it’s still too hot, so evenings work. I put fans near the door, pulling air in to moderate the temperature. I keep trying to pare down to the tools I like to make even better use of the room. I just don’t need 10 ways to do things anymore.” – Stephen England

“About four years ago, I traded some old PVC pipe for a wood stove with a blower. It works very well. Firewood is not a problem. I always have a tree down somewhere on the place.” – Brad Adams

“It’s been a dilemma here in Montana. I have a wood stove in the shop and it works great, except when the wind howls. Here on the plains of Montana it howls a lot. When it’s very cold, the wood stove takes several hours to make it warm enough to work, and sometimes I only want to work for a few hours. I use a diesel space heater to take the initial chill off, but it’s very noisy and smelly. Several years ago I installed an electric space heater. During a very cold February, I used it only to keep the shop above freezing. My shop’s on a separate meter, and the electric bill for the month was over $300. I just installed an 80,000 BTU natural-gas heater. Like Rob, it will be a constant drain on my pocket book, but I’m sure looking forward to it.” – Randy

“I have a large shop (5,000 sq. ft., 20-ft. ceilings) so it is not economically feasible to heat the shop in winter. Still, I have to keep the shop above freezing as the shop is well plumbed, partly for fire suppression and because there is a lot of lumber around. So in the wintertime I keep the shop in the upper 30’s temperature-wise, using a large overhead gas heater. I have not found this to be a problem as a working environment. Wearing a jacket and doing physical work in the main part of the shop is pretty pleasant, and actually I prefer the winter to the hot summer. For fine work, part of the shop has a separate better-insulated room: 10′ x 20′ with electric heat. The joys of a large shop come with some disadvantages. I have quite a bit of frontage on a city street, with two entrances and a big roll-up door, and the street side regularly gets tagged by graffiti ‘artists’, so there is another $95 a month for a graffiti service, which once a month comes around and repaints. With a shop that size, and two heavy steel lumber racks (each 20′ wide and 12′ tall), I use a fork lift for heavy work. Another factor for large shops is lighting. The only solution is industrial lighting fixtures of the type used in warehouses. I use the old high-intensity kind, but as the bulbs burn out I will be replacing them with the new LED versions. One of the most labor-intensive jobs in setting up the shop was the wiring. With 400-amp, three-phase going everywhere, and separate breakers and switches for every machine, installing the 2″ conduit and the many breaker panels was a long job, though my overhead crane (left over from the previous owners) was a really big help; it’s a two-ton crane covering the entire shop. So much for bragging, but my main point is that cold shops are not that bad, except for fine work. I have worked in Switzerland, where many rural homes have a small shop on the hillside, sans heat.” – Robert Lee

“My 24′ x 32′ wood-framed shop is heated by natural gas. It has a 9′ garage door and a utility door. The building is 2×6 construction, insulated and sheeted with chipboard. Heating it adds about 25 to 30 bucks to the gas bill, but I’m warm.” – Don Borgerding

“I live in the Tampa, Florida, area and I just finished installing a split unit A/C to enable comfortable shop time in the hot and humid weather. As you well know, sweat does not mix well with wood or cast iron. It is wonderful to now be able to work out there regardless of the temperature and humidity outside. I am sure you will appreciate your heater as your temps drop.” – Chris Hathaway

“I looked at several expensive options, then installed a vent free 30,000 BTU natural-gas wall mount heater with thermostat and blower. I installed it on the cheap: $400 total, including regulator and flexible gas line. It worked very well last winter and at close to 100 percent efficiency.” – Ed Rosich

“When we moved here 22 years ago, I was lucky enough to have both an understanding wife and some cash left over from the move, so I got one of the ‘Mennonite’ buildings for a terrific price plus the help of a retired electrician who knew things. Anyway, I bought a through-the-wall heat pump. It works just fine unless it is very cold, at which point I add a small heater. I did all the wiring and insulation myself. I added more R-value in insulation than was code, but all in all I am very happy and have minimal cash outlay!” – Chuck Strauss

“I live in the Dallas-Ft. Worth area, so heating really isn’t my problem. The winters are fairly mild, and when it does get cold, I have a small electric radiant heater I place in my shop. My shop is small, about 400 sq. ft. If I get it to 50 to 55 degrees, I am fine. The problem is the summer; I have a small A/C window unit, but it can’t keep it cool and if I open the doors the mosquitoes try to carry me out. They are awful, so I have had to bathe in DEET to work in the shop. Spring and fall are great if you can win the mosquito plague!” – Mark Mckone

“We live in the Sonora desert of Arizona where temperatures inside the workshop range from 60 degrees in the winter to 100 degrees in the summer. The attic is insulated, I have 1-1/2”-thick foam on the garage door and one and a half walls are common to the living area. The remaining walls are block construction. During the pandemic, I found myself spending more time woodworking, so I had to bite the bullet and buy 14,000 BTU portable A/C unit. The instructions say you cannot run the hot exchange air up through the ceiling, so I built a vent that routes it under the garage door (see above photo). I simply open the garage door slightly, place it under the door, release the opener and ease the door on top of this with some boards blocking the rest of the gap. Then I place swimming pool noodles in the gap across the top of the door. When the outdoor temperatures are around 100, I use this setup and a fan blowing from the house through the walk-in door. When outdoor temperatures get to around 110, as it did often this summer, this only helps until it gets too hot to work. Then I have to quit for the day, usually around noon. Below 100, It is a good setup, keeping the shop at around 80 degrees. One problem is, when I do something that my dust collection system can’t control enough dust, I have to close all doors, turn off the A/C and make the sawdust. Otherwise too much dust gets into the house and into the portable A/C unit coils. Blowing cool air from the house is also out of the question when I use chemicals like oil-based finishes. Having a ductless system installed for the garage was a little out of my price range, so this is the best I can do for now. Heating the garage in the winter is done with a space heater of 700 to 1,500 watts, and that does the job real fine. Any time I have critical wood that can’t be exposed to constant changes in temperature and humility, the wood comes into the house for the night or until I need to work on it. If I had it to do over while I was younger, I may re-think the ductless A/C installation.” – JF Praught

“I built a new workshop/garage three years ago in northern Wisconsin, and I planned ahead by putting radiant tubing in the concrete slab and mounted a 90-percent efficient boiler system with plenty of insulation. No blowers are required, like a hanging unit. It maintains heat amazingly with low propane cost, and I can work in there in moccasins. Everything in the workshop is on wheels, so when the blizzards come, I just push everything to the sides and pull the truck in.” – Scott Boyes

“I’m lucky enough to have built an attached shop (15′ x 32′ limited by setback lines) to the existing house, when we moved to northeast Florida a couple years ago. It is well insulated, and I installed a very efficient Daikin one-ton split HVAC heat pump. Not cheap up front, but it does an excellent job of keeping the shop very cool in summer and warm in winter, and it does it for pennies a day! I am very satisfied.” – Rich Dewey

“I have a 20′ x 24′ shop that, at some time before I came along, was added onto the back of my garage. I insulated the dickens out of the four walls and the ceiling. The floor is concrete. There is one double-hung window (facing south), a double-insulated door with a window in each (facing west) and a non-insulated door into the insulated garage. The heater is a gas wall-mount with built-in fan. It is a 15,000 BTU, direct-vent through the wall to the outside that I obtained from Northern Tool. I keep it set at 55 degrees so as to stay above the normal dewpoint to prevent rust. That is warm enough to do small jobs with just a sweatshirt or light jacket. If I want to stay out there for a while, I set it up to 65 degrees and it doesn’t take very long to come up to temp. One day, just for grins and giggles, I set it up to 75 degrees and it had no problem getting there. But that is too hot for me and probably expensive to run.” – Steve Brigham

“I heat my shop with waste oil. I get it from local garages and heat my 42′ x 105′ shop for about $300 a year.” – Tom Hinaman

“I have a 16′ x 32′ pole building that is insulated, although it could use a lot more. Last January, I installed a “Mr. Cool” DIY mini-split and I have been in shop heaven ever since. It is set to auto, 72 degrees, and when it’s cooler out, the heat comes on. When it’s warmer out, well, you get the picture. We did it ourselves, and we love it.” – David Lomas

“Last year I had a 45,000 BTU natural-gas heater installed with direct venting to the outside. Our car and my workshop share the space in a small two-car sized attached garage. I leave the setting on 50 degrees when not in the shop, and I set it to 65 degrees when I’m working in the shop. I looked at the electric option, but yearly cost for electric would have been at least twice as much as gas. It makes working during an Indiana winter much more pleasant.” – Mike Andrews

“With a small 12′ x 20′ shop, I use a window unit to cool and heat my shop here in southeast Texas. It works great — just enough to cool the shop in our terrific summer heat and with enough heat to take the cold edge off in the winter. – Norm Nichols

“I once had a nice ‘weekend’ farm: 72 acres of gently rolling hilltop pastures. I built a BIG 60′ x 40′ pole barn, and inside it I put up a 20′ x 30′ x 10′ insulated enclosure on an 8″ rebar concrete pad. The interior walls were 4′ x 10′ plywood on 2×6 framing. I ran power to the barn, both 120- and 240-volt. I cut a hole in the exterior metal wall to exactly fit a cheap motel type heater/air conditioning unit. I put it up about four feet above grade on a sturdy 2×4 platform. I also put windows in there — one facing into the barn and looking down the slope at the farmhouse I built, and one looking out over two of the pastures. I made the doors 9′ tall so 4×8 plywood would fit easily. Out in the barn, adjacent to the shop, I installed a big, commercial air compressor and an equally large sawdust vacuum collection system. I ran a compressed-air line to a spring reel on the ceiling of the shop and ran a 6″ vacuum line around two walls at 4′ above grade. I ran two lines of power into the shop at waist height, one in 120-volts and one in 240-volts. All my woodworking tools fit nicely! The air compressor, sawdust vacuum, arc welder, HVAC unit, commercial-grade shaper, lathe, planer and 12″ radial arm saw were on 240 volts; all the rest were on 120 volts. Power switches for each vacuum hookup were adjacent to the electrical power outlets. I’d flip the gate up and the switch on for the vacuum when a tool was being used. You could hear the vacuum out in the barn from inside the shop, but just barely. The electric arc welder was out in the barn near where I worked on my race cars. I credit the 240-volt tools and my choice of 2×6 framing and fiberglass insulation for the amazingly small bump in my electric bills. I absolutely LOVED my farm, woodworking shop and the two lakes I put in using a rented bulldozer. I miss the farm but not the ex-wife.” – Gary Domke

“I purchased a 220-volt heater from a shop that went out of business and hung it in a corner from the ceiling. It’s out of the way and it keeps my entire shop toasty, even in the cold Maryland winters.” – Doc Templeton

“Last year, I had a wall-mounted heat pump installed in my garage/shop. It has a condenser outside and remote controls, so I can keep the temp workable in 100-degree heat and 20-degree cold. Of course, one or both cars have to stay outside when I have a project in process. But they haven’t complained…just my wife, who must at times get into a hot or cold car.” – Gary Ahlstrom

“I live down south (Charleston) and my shop is easily cooled with a $140 window air conditioner. Humidity is another issue, so a small dehumidifier is a must to deter rust. Heating my shop back in Indiana where I once lived was a challenge until I installed a natural-gas forced-air furnace. Best money I spent as the temp was maintained at a warm 65 degrees. Open- or closed-fire stoves may seem like a good option, however I think it would be the last choice given the risk of unfriendly fire potential.” – Tony Glotzbach

“I use two Envi heaters. They are wall-mounted convection heaters, and they only draw about three amps max each. I live in Michigan, and it does get cold, but these work. The building is well insulated. I also have two workshop cats that live inside full time. I don’t let them out to play with the coyotes, and they stay nice and warm. I also do not have a rodent problem.” – Chuck Keef

“I have a 24′ x 30′ shop with an electric Modine-style heater in one corner of the shop. The heater, when running, takes a ton of time to overcome the cooled cement slab and machinery. As I am fortunate to have a home automation system, I have built a heat circulator (in the opposite side of my shop) out of PVC pipe and computer muffin fans along with my home-built air filter on the ceiling. My automation maintains the temperature and, when the heater turns on, I also have the air filter and heat circulator turn on. It takes about an hour rather than several hours to bring my temperature recovery from 45 to 68 — pretty good recovery time. As well, it minimizes the runtime of the heater, so I am not using as much electricity for heating. Win/win.” – Lee Bernardo

“I was fortunate to be able to do the following when building a new 17′ x 44′ foot shop space: I started with 2×6 construction, well insulated, and I added an insulated garage door. Then I installed four 1000-watt flat panel infrared heaters, plus enough solar panels to generate more electricity than my house will consume in a year (including the electric heat). Cost per month for electric year-round is the $8 fee the utility charges to connect to their grid.” – Dan Lesan

“After fighting the elements for years, I vowed that if I ever got to build a new shop I would do it right. That chance came two years ago. I built a 26′ x 28′ shop with 12′ sidewalls. I insulated the 2×6 walls to R-19 plus and blew in 10 inches of insulation in the rocked ceiling. I spent the extra money for the best insulated garage door I could buy. Additionally, I placed two 52” ceiling fans to move the air and installed a 50,000 BTU air conditioner with heat tape for the winter. I installed two good windows and a good door with a storm door/screen. I have two overhead infrared heaters over my work area if I need them. I rarely use them. I literally can heat this shop with a candle. It remains a comfortable temperature year round, never falling below 50 degrees in winter with everything off and never over 70 without the air. I have thermostats on everything, so I can go out early when I am going to work in the shop and set the temp to my desired temp. No regrets. Do it right if you ever get the chance.” – Daniel Jerzak

“I live in the San Juaquin Valley in California, where we generally get a late-afternoon delta breeze. So I cool off my garage for the day by running my quiet, cool whole-house fan for an hour in the morning. Earlier this summer I insulated my garage ceiling with R-38 blown-in fiberglass insulation, with an 8″ batt, insulated storage area platform. I access my storage with a fire-rated ceiling pull-down metal ladder. What a difference this makes. I can keep a 20-degree lower temp than the outside. Then, before I finished insulating, I installed a hanging 30,000 BTU gas heater (see photo above) with a thermostat on the wall to help take off the cool edge in the winter. Last summer, I had an insulated garage door installed with good gasketing around the edges. So far, I am very pleased with the results.” – Dennis Hoffman

“Brand new so it’s a bit of a gamble, but when I installed a mini-split heat pump, I had them put one of the indoor units in the workshop. We’ll see how well it survives sawdust; some pre-filtering might be needed. A/C in summer, some heat in winter. I’m also progressively insulating the shop walls. It might not be cost effective if I was worrying about resale, but I view the house as something I live in rather than as an investment; if a modification makes the house better for my needs and isn’t unreasonably expensive, it’s worth considering.” – keshlam

“I have been heating my shop with a barrel wood burner for years. I started out with an Enders wood barrel burning kit probably 25 years ago. My first experience was with a 55-gallon barrel, which would last about two to three years. After several years of replacing the barrels, I got a 60-gallon that I have used for close to 10 years. A couple of years ago, I put a secondary 30-gallon barrel on top of this to allow the heat to be kept around a bit longer. I have cautiously monitored the fire to avoid any unexpected fires. I make sure the fire is on the way out before I leave the shop, which is about 100 yards from the house. My sources of fuel range from project scraps to tree branches. I store these up in clean seed corn bags. I usually add a sack of discarded junk mail for the fire starter. I have scrounged around town when my supply gets low, picking up fallen branches and then cutting them to fit in the bags. My inventory for this winter is fairly good.” – Bob Hantsbarger

“I’m in the process of adding solar to the garage and will also add more panels to the shop when it gets built next year. With over 8 kilowatts of generation, I’ll be using a ductless split system for the shop.” – J. Eric Pennestri

“I was using electric heaters for heat, which were fine. I had no A/C. This summer was brutal on Long Island, and because we couldn’t go anywhere I was spending more time in the shop. I am now in the process of installing a mini-split, which has both heat and A/C. It’s a bit expensive, but I’ll never have to worry about being comfortable in my shop again.” – Al Micucci

“I finally broke down and had one of those mini-splits put in. Best investment ever! I had tried fans in the summer, infrared heaters in the winter. The working conditions still kept me out. I am so glad I now have both heat and air. I only turn it on when I am in my workshop. A bonus: it actually takes care of the entire garage! My workshop is one bay in a three-car garage.” – Katherine

“My shop is a two-car garage. My strategy each year for the changing weather is three-fold. First, I take my two box fans out of my shop and put them in the shed. Second, I take my space heater from the shed and put it in my shop. Third, I change my apparel to the winter line. Sorry I don’t have a long, drawn-out technical lineup of steps taken. In all fairness to the subject, your winters are not like my winters. I live in Dallas. If it gets very far below 40 degrees, I build a fire in the fireplace, lock the shop up and look at things tomorrow when the temperature will be in the mid 60s. Living in Dallas is hard work, but somebody’s got to do it.” – Bill Self

“I use propane to heat my shop for the winter. It works fine and I am quite happy with it. One word of caution when using a heater in your shop: control the dust! The heater has electronic ignition, and I had to replace it because dust got on it and it burned up. This heater did not have any air filtration on it, so I cut up some furnace filters and duct-taped them over the vents. So far, so good! And then there’s the mice…oh, the mice. Yep, mice got into it and chewed up the wiring. It’s the only downside of living in the woods!” – Larry Williams

“I live in Saskatchewan, Canada, where the winter temperatures vary between -20 to 40 degrees centigrade. I heat my shop with a wood pellet stove. The stove keeps the shop temperature between 60 and 70 degrees. The cost per day is approximately $7 Canadian.” – Robert Barbour

“Here in northern New England, heating is a real challenge, and my shop (garage) being shared with our cars makes this doubly tough. My solution is plywood-covered and fully insulated walls (R-15) and R-30 in the ceiling with double-weather-stripped insulated garage doors. Heat is provided by a 25,000 BTU electric heater, as natural gas is unavailable here and propane is too much money when the cost of the tank is factored in. The heater is ceiling-mounted to be out of the way, pointed down at my work area, and it’s supplemented by two ceiling-mounted box fans to help circulate the warm air. Dust control is a must to keep the heater and fan motors clean, and it is provided by shop-built filter units using box fans and furnace filters. Hopefully this year I’ll add a repurposed boxed furnace blower and motor. And since everything is buttoned up and there’s only one window, a dozen overhead LED fixtures light it all up. In January and February it takes about an hour to get the shop temperature up to 60 degrees to allow me to work in a sweatshirt and jeans. Wet floors are handled with a squeegee and a powdered floor dry product commonly used in horse stalls. With this setup, not even a New Hampshire winter can keep me from making sawdust whenever I get the chance.” – Curtis Douglas

“Heat and air are pet issues with me. I live in southwest Oklahoma, and I know about both. I have, what I believe, is a dream workshop. It’s a four-car garage that has never seen a car. It’s attached to the house, so when I’m working, there is little temperature differential through the one door to the utility room. I cannot work with sweat dripping from my eyebrows and nose. Nor can I work when I’m cold or wearing three layers of clothing. First, my workshop is used daily. It saves my sanity and that of my wife. It’s my world; her world is the house. Secondly, it is essential for maintenance of 15 acres, a large house and 10 grandkids. I recognized years ago that our climate required heat and air to survive. Life here is miserable without it. I have a propane heater hanging from the ceiling and totally out of the way. I attached a thermostat, and the shop is as comfortable as the house. A large window A/C keeps temperatures cool in our very hot summers. The walls and ceiling are insulated to the max. Once I made my mind up to stand the cost of purchase and the cost of operation, I became very happy with the results. I use the workshop every day, now, and I look forward to it. If you can afford a workshop, you can afford to make it comfortable enough to use it.” – Don Wooley

“I go with the flow. You can’t change Mother Nature, and I love woodworking, so I just put up with it. I have a small heater in my shop to just take the chill off. I use fans in the summertime.” – Robert Ahlgrim

“To heat my 32′ x 26′ shop, I purchased a used heater sourced on the local Craigslist. Not having natural gas to the shop, I looked for an LP heater. Once the heater was sourced and installed, I contacted a local LP supplier and arranged to have two large LP tanks installed and the piping run to the heater. With the thermostat set at 40 degrees, there is no concern about items in the shop freezing. The heater can bring the temperature in the shop from 40 to 70 degrees in about 15 minutes. In the photo above, my heater can be seen in the upper left corner. It is suspended from the building trusses and exhausts through the end wall of the building.” – C. Ronald Farver

“Living here in south central Pennsylvania, we get to enjoy all four seasons at their best. Unfortunately, this also means we’re required to adopt a three-pronged approach to shop environmental control: heat, cooling and humidity control. The wood stove handles the heating quite well (and disposes of my mistakes), a mid-sized window air conditioner provides cooling sufficient for all but the hottest days and a residential dehumidifier helps when the other two units aren’t drying the air. The dehumidifier is plumbed to continuously drain outside, so there’s no emptying required. I estimate the energy usage for the electrical units is about $50 to $60 per year. The wood stove operates mostly for free (I make a LOT of mistakes). Additionally, shop design can have a big effect on shop comfort. My 600-sq.-ft. freestanding shop has R-11 insulation on the ceiling and sides. It is situated north of a stand of deciduous trees that block the summer sun and allow the winter sun to enter the mostly glass south wall. The south end of the shop also has a large roof overhang sized to block most of the summer sun and allows the winter sun to extend almost to the north wall. These south windows also provide great lighting for aging eyes.” – Gregory Harmon

“I am waiting for my 20′ x 24′ shop to get here and be assembled. It will not be insulated to start with. I am looking at several heating options, the most interesting being the ‘Rocket Stove’ with a mass big enough to hold a lot of the heat and release it slowly. Heating with wood scraps and leftovers sounds like a good idea to me. I am caretaker for 40 wooded acres in central Oklahoma, so lots of twigs and scrap from that. I am not burning next week’s project just to stay warm.” – RileyG

“My shop is a free-standing 24′ x 30′ building in northwest Georgia. While building it two years ago, I asked the advice of several HVAC contractors as to what they would recommend for heating and cooling. The choice came down to either a through-the-wall unit (I call that a ‘hotel unit’) or a mini-split. Trade off was original cost. Mini-split was a couple of hundred dollars more but should use less electricity. I went with the mini-split and am very satisfied. Comfort is great summer and winter for me and the shop cat. Our electrical rates are reasonable, as the power is generated by TVA.” – Jay Simmons